L1 Certification Launch

Last updated December 24, 2023

As a member of the Tufts SEDS Rocketry team, I undertook the construction of a high-powered rocket for my NAR

L1 certification. In addition to fulfilling the certification requirements, I aimed to explore the use of a

3D-printed ABS motor mount that also served as the fin assembly. My objective was to assess the

in-flight and

post-flight reliability of the motor mount and its ability to withstand potential warping or material

alterations caused by the rocket motor.

3D-printed Motor Mount

The 3D-printed motor mount offered a convenient alternative to traditional rocket designs, which typically

involve separate components such as centering rings, an engine block, and ejection charge protection. In

contrast, the 3D-printed motor mount eliminated the need for these individual elements, simplifying the

overall

assembly process.

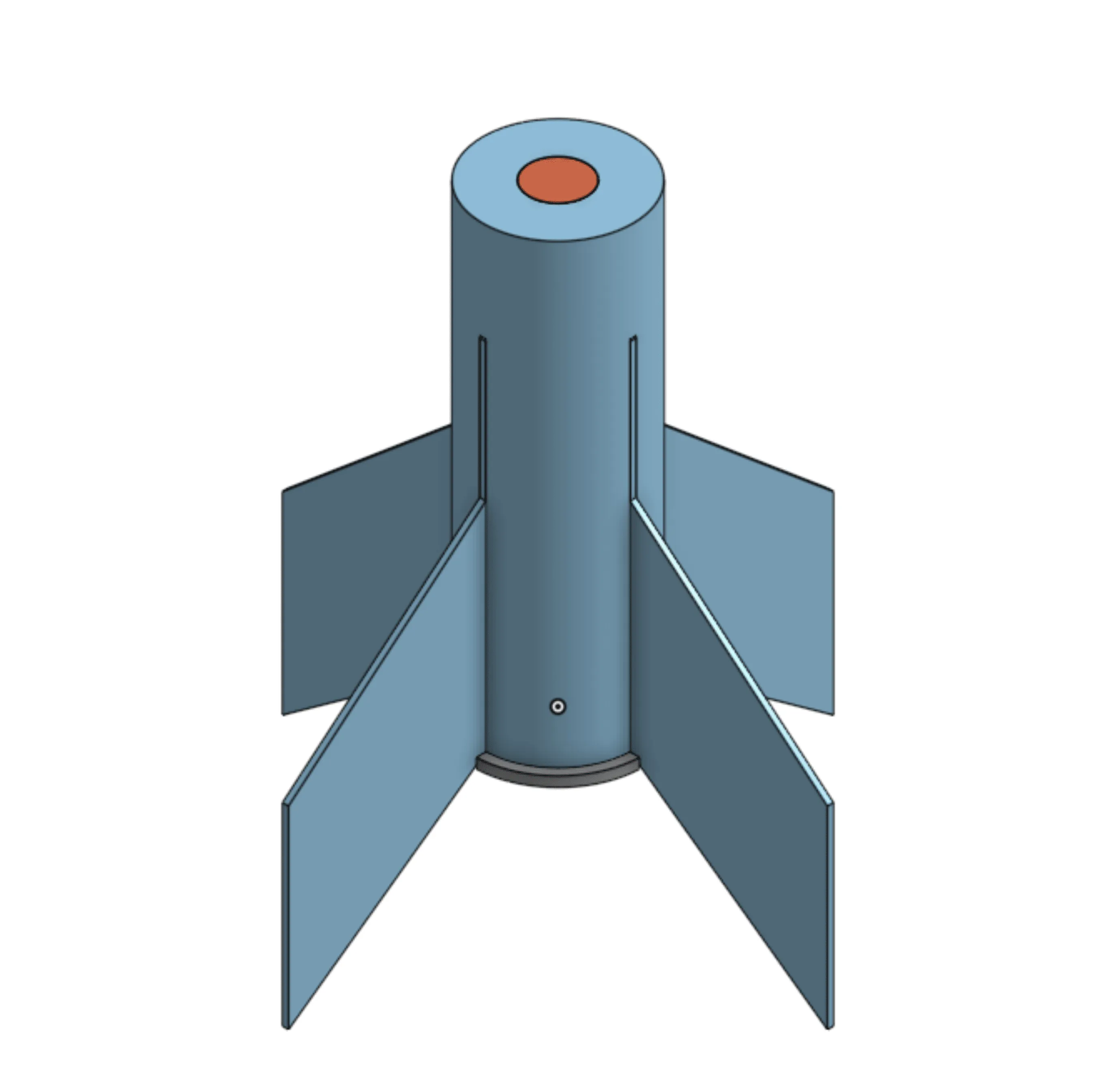

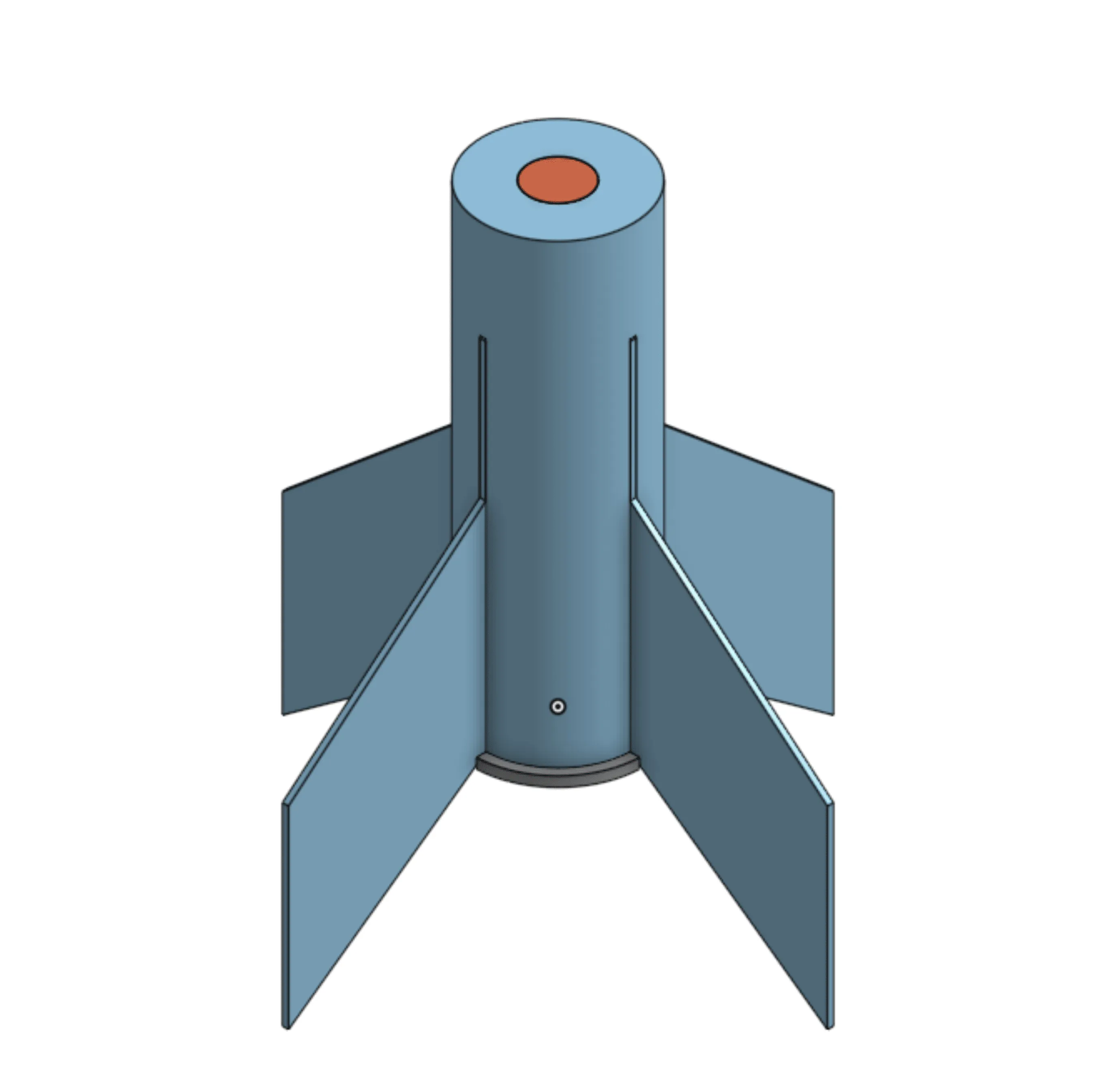

CAD model of the completed 3D-printed

motor mount

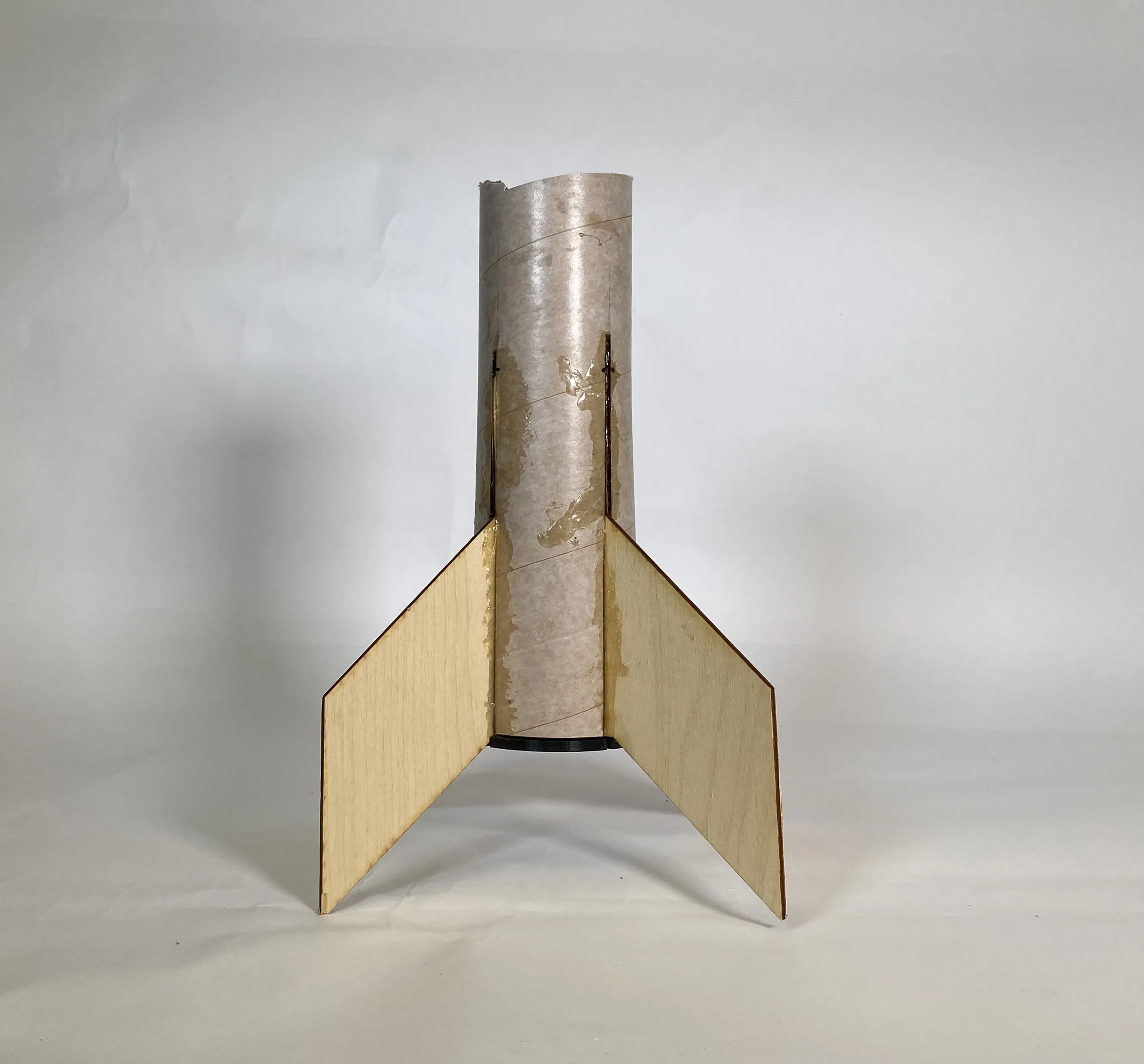

Post-launch photo of the motor mount

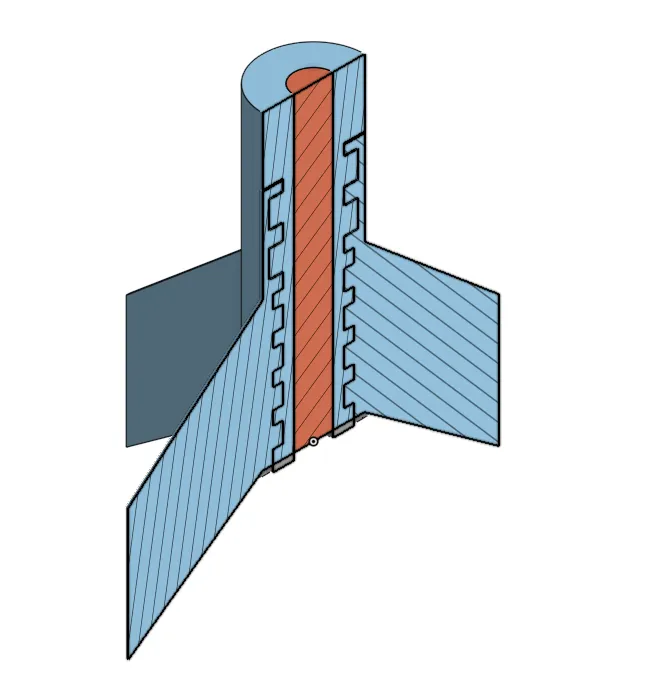

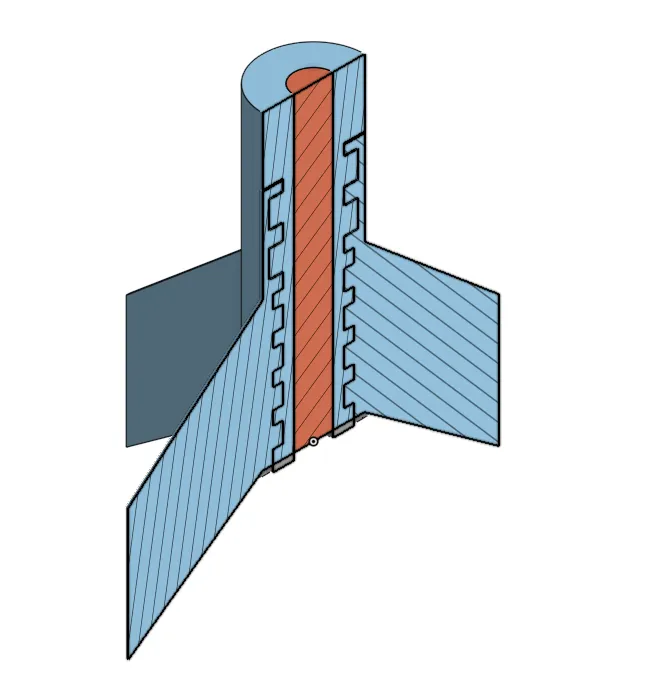

Furthermore, the motor mount integrated the fin attachments seamlessly. Each of the four designated fin

slits

featured a jigsaw-like slot that not only provided a snug fit for the fins but also secured a significant

portion of each fin within the motor mount. This structural stability ensured the fin assembly remained

intact

during flight, effectively preventing any mid-flight damage resulting from excessive aerodynamic loads or

flutter.

Sectional view of motor mount

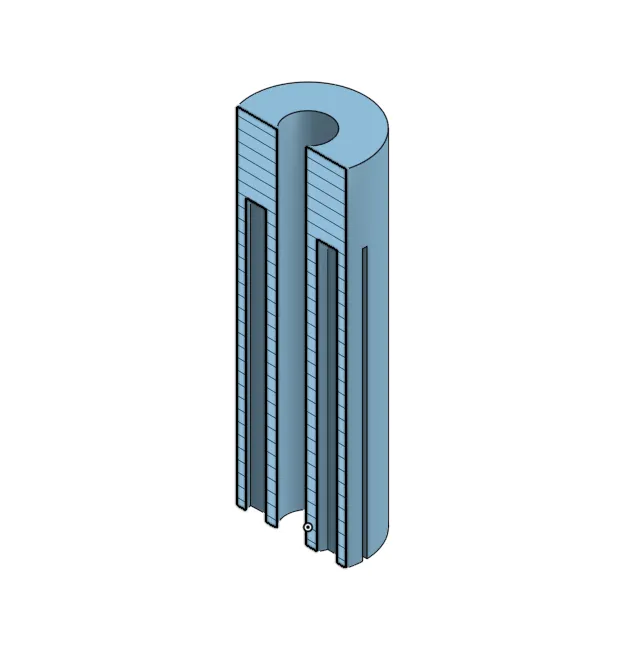

It's worth noting that the motor mount incorporated four hollowed spaces intentionally, reducing both the

weight of the assembly and the amount of ABS material used.

Launch Results

The flight proved to be a success. The rocket soared off the launch pad, reaching an altitude of 838.2 meters

(2750 feet),

before descending and landing safely with the parachute. Surprisingly, despite being entirely printed in ABS,

the rocket performed exceptionally well in terms of speed and apogee. For future iterations, I plan to explore

techniques such as variable density printing to reduce infill density in non-critical areas and employ topology

optimization to meet specific criteria for each section of the motor mount.

Overall, the 3D-printed motor mount showcased its potential as a reliable and lightweight component,

demonstrating promising possibilities for optimizing rocket designs and performance.